Marginal fit of two CAD/CAM Restorations Using Different Impression Materials

Ezzedden Ragab Alhur1

Faculty of dentistry, almergab university Libya

Email: dr.ezzofree77@gmail.com

HNSJ, 2024, 5(11); https://doi.org/10.53796/hnsj511/10

Published at 01/11/2024 Accepted at 20/10/2024

Citation Methods

Abstract

There are multiple impression materials available in our market. So many investigations are needed to evaluate their accuracy which effect of the marginal fit of the final restoration. there is no significant different between all the investigating materials as regard their accuracy.

Introduction: impression material is used to record the intraoral structure. Ideally the material should be extremely accurate, and virtually distortion free. The accuracy allows to record minute details without taking additional impression. The material is very soft elastic & resistance to tear while removes from the undercut. (1)

Prosthetic restorations that fit poorly may affect the periodontal health and occlusion. The design of the tooth preparation is an important consideration in tooth reconstruction. The use of certain geometric features in preparations for full coverage restorations has been based largely on experience and individual preference. (2)

The dimensional changes of the impression materials may affect the quality of fit and retention of the restoration, which influence the success of indirect restorative procedures.(3,4,6) The dimensional behavior of impression material, is influenced by humidity, the time interval from mixing to pouring, and the thickness of the layer of material in the tray. In addition, impression materials contract with the temperature change from the oral cavity to the external environment due to their linear expansion thermal coefficient (3).

New generation of impression materials keep immersing in dental market every day, so more investigations are needed to study their properties and qualify their uses.

This study was conducted to evaluate which of these materials could provide accurate seating of the final restoration.

Material and method: this study was made to evaluate the accuracy of three different impression materials using two ceramic materials used in this study were zirconia and Lithium disilicate using machinable Computer Aided Design / Computer Aided Manufacturing (CAD/CAM) (CEREC in Lab), impression materials used in this study:

Methodology:

Samples grouping:

The impression materials were grouped as follows:

Group (I) Laminated hydrocolloid technique. Group (II) Addition Silicone impression materials. Group (III) Polyether impression materials.

For each group, specimens were subdivided into two subgroups according to the ceramic material used:

Subgroup (A) Zirconia (15 samples)

from each impression material: 5 non anatomical cad/cam ceramic crowns were fabricated. Subgroup (B) Lithium disilicate (15 samples) for each impression material: 5 non anatomic cad/cam ceramic crowns were fabricated.

Dies fabrication

For the purpose of standardization, a custom made master die, representing full all ceramic crown preparation was constructed for impression making standardization. A perforated custom made tray was fabricated that could be placed in the same position on the master die for each impression.

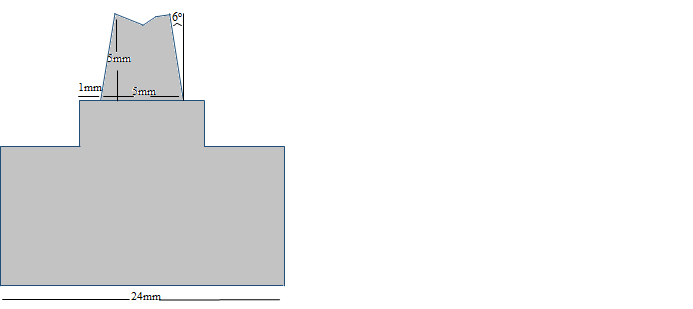

The metal master die was prepared by a milling machine to resemble a prepared mandibular second premolar with 5mm height and 5mm width at the base, the occlusal taper was 6°. The occlusal surface was prepared with 2 sloping surfaces, one of which was slightly beveled. The preparation was finished with a 1-mm-wide rounded shoulder finish line. This design was chosen to prevent rotation of the crowns on the die and also to ensure that their placement could be reproduced on the die. four equidistant marks were engraved on the die to oriented the stereomicroscope. the die has a 24mm diameter base to ensure proper handling (Fig1 a, b)

(Fig1a,b) Stainless Steal die.

Custom made perforated tray:

Each custom made perforated tray was cylindrical in shape with inner diameter 7mm (to accommodate with the base of the mater die) and inner height 7mm were made to act as a tray for accommodating the impression materials(56) (Fig2).

Impression making

One impression was made for each material on the same metal die using perforated trays. All fabrication procedures were accomplished according to the manufacturer’s instructions for each tested material used.

(1) laminated hydrocolloid technique:

Impressions were taken using agar alginate impression material. The agar was warmed in boiling water for about six min. The agar was stored for at least 10 min at 65°C before being syringed around the preparations. A mix of alginate according manufactures instructions, and was placed in a custom-made perforated tray and it was immediately seated over the agar syringe material. The alginate was set, the combined impression is removed. fig (3)

(2) The polyvinyl siloxane impression:

The single step impression technique was used for the heavy bodied material was injected to the custom made perforated trays. At the same time the light bodied material was injected on the die. The impression tray was then centered over the die and seated, Initially, finger pressure was applied to allowed accurate seating and the escape of any excess material. After complete setting the tray was removed from the die in sharp snap removal parallel to the long axis of the die. fig (4).

(3) Polyether impression materials:

Two equal lines of impression base paste and catalyst were spread on paper pad and mixing was done by a metal spatula in circular strokes for producing homogenous mixed impression. Then load on a perforated tray, and apply the mixture into the die. The impression tray was then centered over the die. After complete setting the tray was removal parallel to the long axis of the die.

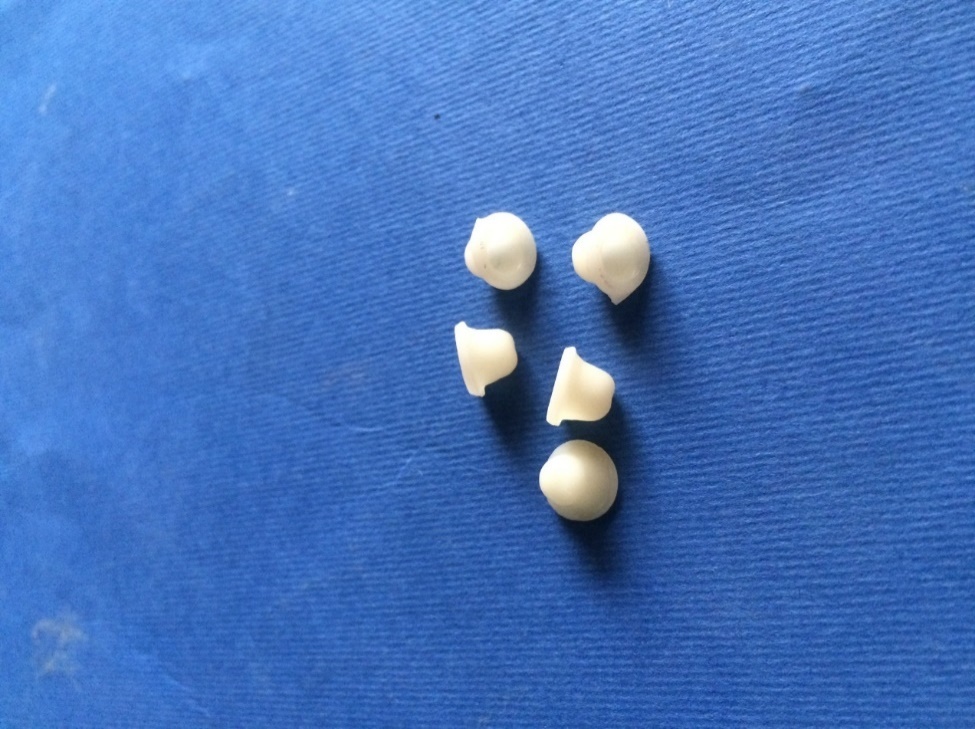

Crowns construction:

For each material. crowns were constructed according to the manufacturer’s instructions in the shape of non-anatomical cylindrical crowns of 6mm diameter, 7mm height,2mm occlusal thickness and margin thickness 1mm (fig.6)

All tested crowns were individually seated on the stainless steel die and were examined for vertical marginal fit with respect to the die.

Testing Procedures:

Testing Procedures:

Cervical marginal accuracy: of their seating on the stainless steel die and to hold them in place during the examination with a stereomicroscope. Shots of the margins were taken for each crown using digital camera**fitted on the stereomicroscope using a fixed magnification of 40X (fig20ab).

.*Carl Zeiss stereomicroscope, Germany.

**Olympus Camedia C-5060 digital camera, Japan.

Figure (20 a,b ) Olympus camedia C-5060 digital camera fitted on Carl Zeiss Steroemicroscope

Then morphometric measurements were done on an IBM compatible personal computer (PC)*. After that the software **, which was used for image analysis was calibrated, the vertical gap distance was measured for each shot [ “6” equidistant landmarks along the cervical circumference for each crown (Mesio-buccal, mid-buccal, disto-buccal, mesio-lingual, mid- lingual, and disto- lingual line angles). Measurement at each point was repeated five times].Then the data obtained were collected, tabulated and then subjected to statistical analysis.

Vertical marginal gap

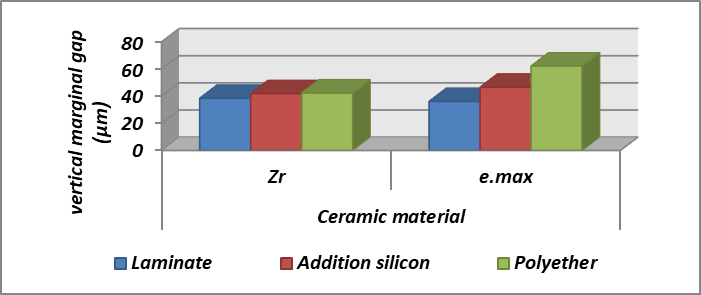

The mean values and standard deviation of vertical marginal gap (µm) as function of ceramic and impression materials are summarized in table (5) and graphically drawn in figure (21). The results revealed that e-max cad restoration gave highest marginal gap (62.19) with polyether impression material ,while gave lowest marginal gap with laminate impression techniqe.

Table (5 ) Vertical marginal gap results (Mean values± SDs) as function of ceramic and impression materials

|

Variables |

Ceramics |

Statistics |

||||||

|

Zr |

e.max |

t-test |

||||||

|

Mean |

SD |

Mean |

SD |

P value |

||||

|

Impression materials |

Laminate |

38.41Aa |

19.87 |

36.12Ca |

9.44 |

0.5635 ns |

||

|

Addition silicon |

41.83Aa |

10.67 |

46.57Ba |

11.04 |

0.0718 ns |

|||

|

Polyether |

42.34Ab |

10.14 |

62.19Aa |

18.99 |

<0.0001* |

|||

|

Statistics |

ANOVA (P value) |

0.4795 ns |

<0.0001* |

|||||

Different large superscript letter in the same column indicating statistically significant difference among impression (p < 0.05) Different small subscript letter in the same row indicating statistically significant difference among ceramic (p < 0.05) *;significant (p < 0.05) ns; non-significant (p>0.05)

Figure (21 ) Histogram of vertical marginal gap mean values as function of ceramic and impression materials

Table (6 ) Two factorial analysis of variance ANOVA test of significance comparing variables affecting vertical marginal gap mean values

|

Source of Variation |

Df |

SS |

MS |

F |

P value |

|

Ceramics |

1 |

3978.95335 |

3978.95335 |

13.2411 |

0.0003* |

|

Impression materials |

2 |

10817.70351 |

5408.85176 |

17.6926 |

<0.0001* |

|

Interaction |

2 |

6141.01819 |

3070.50909 |

10.0438 |

<0.0001* |

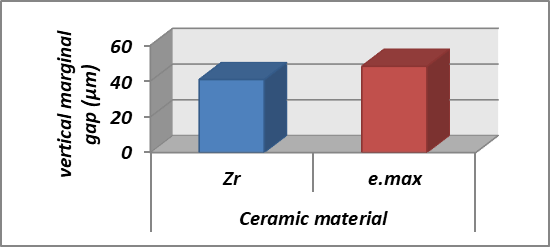

Effect of ceramic

Regardless to impression materials, totally it was found that e.max group recorded statistically significant (P<0.05) higher vertical marginal gap mean value (48.29± 9.26 µm) than Zr group (40.86± 1.63 µm) as indicated by two way ANOVA followed by pair-wise Tukey’s post-hoc tests

Table ( 7) Comparison between total vertical marginal gap results (Mean values± SDs) as function of ceramic

|

Variable |

Mean |

SD |

Tukey’s rank |

Statistics (P value) |

|

|

Ceramic |

Zr |

40.86 |

1.63 |

B |

0.0003* |

|

e.max |

48.29 |

9.26 |

A |

||

Different letter in the same column indicating statistically significant difference (p < 0.05)

*; significant (p < 0.05) ns; non-significant (p>0.05)

Figure (22 ) A column chart of total vertical marginal gap mean values as function of ceramics

INTERACTION BETWEEN VARIABLES

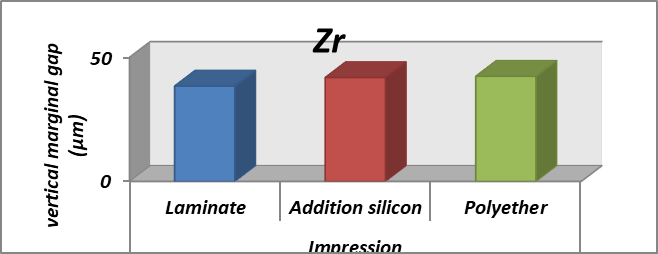

Zr group

it was found that Polyether group recorded statistically non-significant (P>0.05) highest vertical marginal gap mean value (42.34± 10.14 µm) followed by Addition silicon group (41.83± 10.67 µm) while Laminate group recorded statistically non-significant (P>0.05) lowest vertical marginal gap mean value (38.41± 19.87 µm) as indicated by one way ANOVA followed by pair-wise Tukey’s post-hoc tests

Table (8 ) Vertical marginal gap results (Mean values± SDs) for Zr group as function of impression materials

|

Variables |

Ceramic |

Statistics |

|||

|

Zr |

ANOVA |

||||

|

Mean |

SD |

P value |

|||

|

Impression materials |

Laminate |

38.41A |

19.87 |

0.4795 ns |

|

|

Addition silicon |

41.83A |

10.67 |

|||

|

Polyether |

42.34A |

10.14 |

|||

Different large superscript letter in the same column indicating statistically significant difference (p < 0.05) *; significant (p < 0.05) ns; non-significant (p>0.05)

Figure (24 ) A column chart of vertical marginal gap mean values for Zr group as function of impression materials

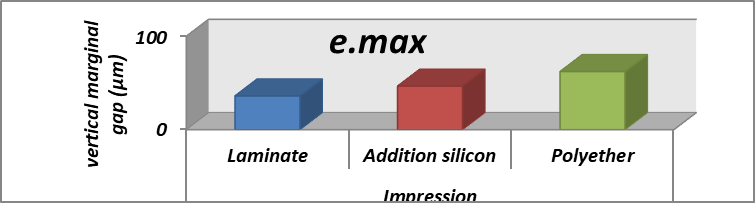

e.max group

it was found that Polyether group recorded statistically significant (P<0.05) highest vertical marginal gap mean value (62.19± 18.99 µm) followed by Addition silicon group (46.57± 11.04 µm) while Laminate group recorded statistically significant (P<0.05) lowest vertical marginal gap mean value (36.12± 9.44 µm) as indicated by two way ANOVA followed by pair-wise Tukey’s post-hoc tests.

Table (9 ) Vertical marginal gap results (Mean values± SDs) for e.max group as function of impression materials

|

Variables |

Ceramic |

Statistics |

|||

|

e.max |

ANOVA |

||||

|

Mean |

SD |

P value |

|||

|

Impression materials |

Laminate |

36.12C |

9.44 |

<0.0001* |

|

|

Addition silicon |

46.57B |

11.04 |

|||

|

Polyether |

62.19A |

18.99 |

|||

Different large superscript letter in the same column indicating statistically significant difference (p < 0.05) *; significant (p < 0.05) ns; non-significant (p>0.05)

Figure (25 ) A column chart of vertical marginal gap mean values for e.max group as function of impression materials

Discussion

The transfer of an accurate replication of the patient’s hard and soft tissue to the dental laboratory is of critical importance in the fabrication of fixed or removable restoration. Making a definitive impression is a critical step in producing biologically, mechanically, functionally and esthetically acceptable restorations (84). The ability to produce a smooth surface and accurate detail on stone models is one of the most important factors for the impression used in fixed prosthodontics (59).

In this study we evaluated the marginal accuracy of different impression materials using two ceramic materials by machinable Computer Aided Design / Computer Aided Manufacturing (CAD/CAM).

In order to achieve this goal, an accurately designed protocol of the methodology was adopted. The in-vitro investigations can help in the estimation of the in-vivo usability of new dental materials and products(101)

The introduction of impression technique, laminated hydrocolloid technique, was examined in comparison with other popular accurate impression materials (vinyl polysiloxane and polyether).

A combination between reversible (agar) and irreversible hydrocolloid (alginate) impression system had been introduced in the dental profession recently.This combination is known as ‘laminated hydrocolloid technique’.In this technique, reversible hydrocolloid was injected onto the prepared tooth then custom tray loaded with irreversible hydrocolloid was positioned over the reversible hydrocolloid. During this process, alginate gelated by chemical reaction, at the same time, agar gelated by contacting cool alginate rather than cooled water tray (94).

The technique simplifies the use of agar and provides an impression surface that allows for preparation of stone casts acceptable for crown and bridge applications. (7)

Summary & Conclusion

This in vitro study investigated the marginal accuracy of different impression materials using two ceramic materials by machinable Computer Aided Design / Computer Aided Manufacturing (CAD/CAM).

The results of this study showed:

- Laminated hydrocolloid agar-alginate impression techniques have significant lowest marginal gap than polyvinyl and polyether.

- For zirconia copings group it was found that non-significant difference in marginal gap between polyether and polyvinyl impression materials.

- For e.max cad copings group it was found that there is significant difference marginal gap between polyether and polyvinyl impression materials.

Within the limitation of this study, the following conclusions were drawn:

Laminated hydrocolloid agar-alginate impression technique can be used as secondary impression with high accuracy.

References

1.Kronström MH, Johnson GH, Hompeschc RW (2010), ‘Accuracy of a new ring-opening metathesis elastomeric dental impression material with spray and immersion disinfection’, J Prosthet Dent vol. 103 pp 23-30.

2.Quintas AF, Oliveira F, Bottino MA.: “Vertical marginal discrepancy of ceramic copings with different ceramic materials, finish lines, and luting agents.” J Prosthet Dent. 2004; 92:250-257

3. Shah S, Sundaram G, David B and Sherriff M : The use of a3D laser scanner using software superimposition to assess the accuracy of impression techniques. J. Dent., 2004; 32:653.658.

4. Marcinack CF, Young FA, Draughn RA and FlemmingWR: Linear dimensional changes in elastic impression materials. Dent. Res., 1980; 59:1152.1155.

5. Mehta R, Wadhwa S, Duggal N, Kumar A2, Goel M and Pande S: Influence of Repeat Pours of Addition Silicone Impressions on the Dimensional Accuracy of Casts. J Interdiscipl Med Dent Sci 2014; 2:1.

6. Chen SY, Liang WM and Chen FN: Factors affecting the accuracy of elastomeric impression materials. J. Dent., 2004; 32:603.609.

7. R.G. CRAIG, Reiviw of dental impression materials Presented at the International State-of-the-Art Conference on Restorative Dental Materials, Adv Dent Res 2(l):51-64, August, 1988

8. Groten MS, Girthofer S, Probster L. Marginal fit consistency of copy-milled allceramic crowns during fabrication by light and scanning electron microscopic analysis in vitro. J Oral Rehabil 1997;24:871-81

9.Gassino G, Barone Monfrin S, Scanu M, Spina G, Preti G. Marginal adaptation of fixed prosthodontics: A new in vitro 360-degree external examination procedure. Int J Prosthodont 2004;17:218-23.

10.Gu XH, Kern M Gu XH, Kern M. Marginal discrepancies and leakage of all-ceramic crowns: influence of luting agents and aging conditions. Int J Prosthodont 2003;16:109-16.

11. Albert FE, El-Mowafy O. M. Marginal adaptation and microleakage of Procera AllCeram crowns with four cements. Int J. Prosthodont 2004;17:529-35.

12. Vahidi F and Egloff E, panno F , Evalution of marginal adaption of all-ceramic crowns and metal ceramic crown . J Prosth dent 63:426,1991

13. Clpe X, James L, Martin F. Bond strength and accuracy of combined reversible-irreversible hydrocolloid impression system. J Prosthet Dent 1992;67(5):621-32.

14. Karatasli O, Kursoglu P, Çapa N, Kazazoglu E. Comparison of the marginal fit of different coping materials and designs produced by computer aided manufacturing systems. Dent Mater J 2011;30(1).

15. Jidige Vamshi Krishna, sumanth Kumar, Ravindra Savadi.: Evolution of metal-free ceramics. J.india prosth.2009;11:72-74

16. Anusavice KJ and Kenneth J: Phillips’ science of dental materials. 11th edition. Elsevier 2003. p. 12.

17. Craig RG: Restorative Dental Materials (ed 11). St Louis,Elsevier, 2001. 48-58.

18.Schneider W.: No compromises the new CEREC MC XL and inLab MC XL milling machines. Int. J. Comput.Dent. 2007;10:119-126

19.Kurbad A.: CEREC goes inLab the metamorphosis of the system.Int. J. Comput. Dent. 2001;4:125-

20. Appleby DC. The combination of hydrocolloid/alginate impression. JADA 1983;106:194-

21. Anusavice KJ: Phillips’ Science of Dental Materials (ed 11). Philadelphia, Saunders, 2003, p. 216.

22.Helmer J.D., Driskell T.D.: Research on bioceramics. Symposium on Use of Ceramics as Surgical Implants. South Carolina, USA: Clemson University; 1969

23. Hembree JH JR and Nunes LJ : effect of moisture on polyether impression materials. J Am Dent Assoc. 1974; 89(5): 1134-6.

24. Klettke T, Kuppermann B, Führer C, and Richter B: Hydrophilicity of Precision Impression Materials During Working Time. 3M ESPE AG, Seefeld, Germany.

25.Green D., Hannink R., Swain M.: Transformation toughening of ceramics. Boca Raton, FL: CRC Press; 1988

26.Hannink R.H.J., Kelly P.M., Muddle B.C.: Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000;83:461–487

27. Skinner WE, Hoblet N. A study of accuracy hydrocolloid impression. J Prosthet Dent 1956;6(1):80-8

28. Sorensen J, Astandared method for determination of crawon margin fidelity ,J Prosthet Dent 1990;64:18-24.

29, Melean W Wilson D , prosser J . Development and use of water hardening glass ionomer luting cement . J Prosthet Dent 1984;52:175-81

30. Shakila Fatemaa, Sheikh Md. Shahriar Quaderb, Mohammad Shamsuzzamanc,Mirza Md. Arifur Rahmand, Nasima Khane A Comparative Study on Accuracy and Reproducibility of Alginate and Addition Reaction Silicone as an Impression Materials Updat Dent. Coll .j 2013; 3(2):28-33.

31.Felton D, Kanoy B, Bayne S and Wirthman G . effect of in vivo crown margin discrpancies on periodental health . J Prosthet Dent 1991;65:357-64.

32. Hondrum S. O.: A review of the strength properties of dental ceramics. J. prosth. Dent. 1992;67:859-33.Swab J.J.: Low temperature degradation of Y-TZP materials. Journal of Materials Science 1991;26:6706–6714

34.Luthardt R.G., Holzhuter M., Sandkuhl O., Herold V., Schnapp J.D., Kuhlisch E.: Reliability and properties of ground Y-TZP-zirconia ceramics. Journal of Dental Research 2002;81:487–491

35.Kosmac T., Oblak C., Jevnikar P., Funduk N., Marion L.: The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dental Materials 1999;15:426–433

36. Pera P., Gilodi S., Bassi F., Carossa S.: In-vitro marginal adaptation of alumina porcelain ceramic crowns. J. Prosthet. Dent.1994;72:585-590

37. Wolfart S Wegner SM, AL-Halabi A and Kern M. Clinical evalution of marginal fit of new all ceramic system befor and after cemention. Int J Prosthodont 2003;16:587

38. . Park SH, Lee KB. A comparison of the fidelity between various cores fabricated with CAD/CAM system. J Kor Acad Prosthodont 2008;43(3): 269-78

39. Atousa Azarbal, marginal fit comparison of cad/cam crowns milled from two different materials University of Pittsburgh, 2015;24:871-88

40 . Tinschert J, Natt G, Mautsch W, Spiekermann H. Marginal fit of alumina- and zirconia-based fixed partial dentures produced by a CAD/CAM system. Oper Dent 2001;26:367-74.

41. Beuer F, Aggstaller H, Edelhoff D, Gernet W, Sorensen J. Marginal and internal fits of fixed dental prostheses zirconia retainers. Dent Mater 2009;25:94-102.

42. Donovan TE, and Chee, WW: A review of contemporary impression materials and techniques. Dent. Clin. N. Am., 2004;48:445.470.

43. APPLEBY, D.C.; PAMEIJER, C.H.; and BOFFA, J. (1980): The Combined Reversible Hydrocolloid/Irreversible Hydrocolloid Impression System, / Prosthet Dent 44:27-35.

44. Giordano R: Impression materials: basic properties. GenDent 2000; 48:510-516.

45. Appleby DC, Cohen SR. The combined reversible/irreversible hydrocolloid impression system: Clinical implication. J Prosthet Dent 1981;46(1):48-58

46. Heering HW, Tames MA. Comparison of the dimensional accuracy of a combined reversible/irreversible hydrocolloid impression system with commonly used impression materials. J Prosthet Dent 1984;52(6):795-99.

47. Pace SL. Polyvinyl impression materials vs. alginate impression materials. Contemp Dental Assisting. Feb 2006:20-23.

48. Dabas N, Dabas A, Arora A and Yadav H: Comparative evaluation of dimensional accuracy of casts generated from multiple mix impression technique, matrix impression system and dual arch impression technique – An in vitro study. J Pierre Fauchard acad 2013; 27:23-27.

49.Wadhwani CP, Johnson GH, Lepe X and Raigrodski AJ: Accuracy of newly formulated fast-setting elastomeric impression materials. J Prosthet Dent. 2005; 93(6):530-9

50. Stappert CF, Att W, Gerds T, Strub JR. Fracture resistance of different partial-coverage ceramic molar restorations: An in vitro investigation. J Am Dent Assoc 2006;137(4):514-22.

51. Morena R, Beaudreau GM, Lockwood PE, Evans AL, Fairhurst CW, Fatigue of dental ceramics in a stimulated oral environment . J Dent Res;65:993-7(1986).

52. Tysowsky GW .The science behind lithium disilicate : a metal free alternative .Dentistry Today;3:25(2009).

53.Piconi C., Maccauro G.: Zirconia as a ceramic biomaterial. Biomaterials.1999;20:1-25

54.Garvie R.C., Hannink R.H., Pascoe R.T.: Ceramic steel Nature 1975;258:703–704

55. Scientefic Documentation IPS e.max CAD page 4-30.

56.American National Standard / American Dental Association: Specification no. 19 for non-aqueous, elastic dental impressions. JADA 1977; 94: 733-741. Addendum 1982;105:686.

57. Ferrari M., Mason N., Poli L.: Marginal adaptation of crowns: a scanning electron microscopic investigation. Int. J. Periodontics and Restorative Dentistry.1994;14: 273

58. Beschnidt M., Strub R.: Evaluation of the marginal accuracy of different all-ceramic crown systems after simulation in the artificial mouth. J. Oral Rehabil. 1999;26:582-593

59.Wassell RW, Baker D and Walls AWG : Crown and other extracoronal restorations : impression materials and techniques. Br Dent J 2002;

60. Valderhaug J., Birkeland M.: Periodontal conditions in patients 5 years following insertion of fixed prostheses. J. Oral Rehabil.1976;3:237-243

61. Shearer B., Gough B., and Setchel J.: Influence of marginal configuration and porcelain addition on the fit of In-Ceram crowns. Biomaterials,1996;17:1891-1895

62. Lang P., Kiel A., Anderhalden K.: Clinical and microbiological effects of subgingival restorations with overhanging or clinical perfect margins. J. Clin. Periodontol.1983;10:563-578

63. Petteno D., Schierano G., Bassi F., Carossa S.: Comparison of marginal fit of three different metal-ceramic systems: An in vitro study. Int. J. Prosthodont. 2002;13:405-408

64. Groten M., Girthofer S., Probster L:. Marginal fit consistency of copy-milled all-ceramic crowns during fabrication by light and scanning electron microscopic analysis in vitro. J. Oral Rehabilitation.1997;24;871-881

65. Goldman M, Laosonthorn P, White RR.: Microleakage-full crowns and the dental pulp. J Endo 1982;18:473-475

66- Christina MA, Maria PR, William DH.: Nondestructive, in vitro quantification of crown margins. J Prosthet Dent 2001; 85:575-584.